Dollar Mason began as the emblem with the “best tee.” Now in the event that they fall brief, they’ve nobody guilty however themselves.

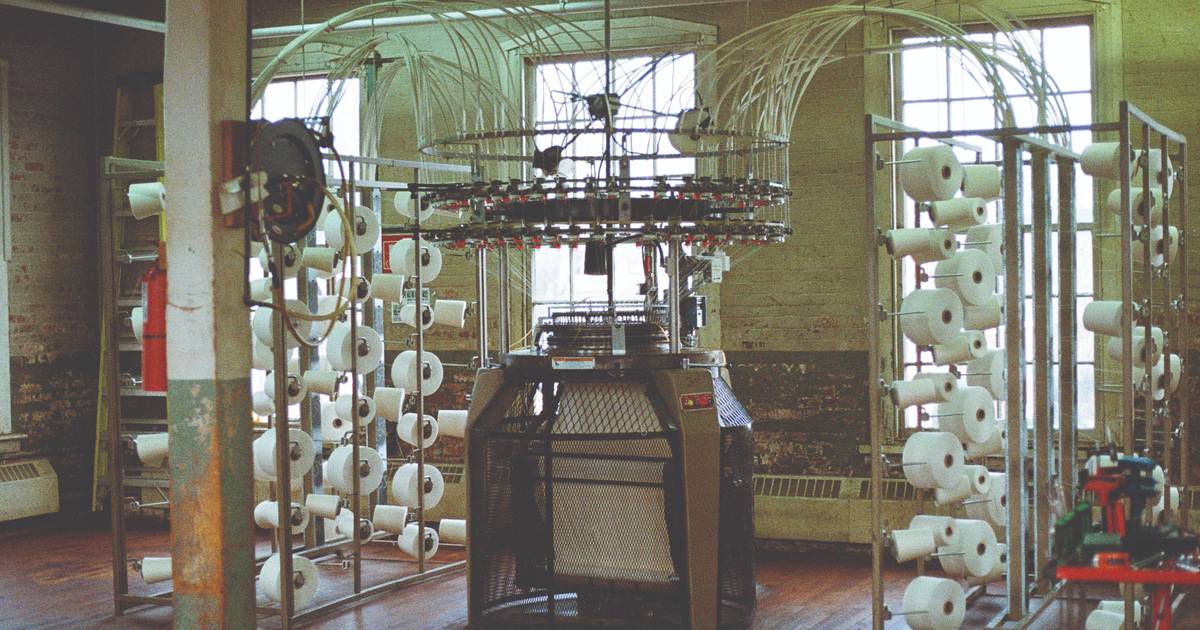

Remaining December, the emblem, which began on-line in 2013 and now has over 20 retail outlets in the United States, got a closed knitting mill in Pennsylvania. Lately, it makes its most well liked T-shirts there.

The verdict to get into production was once in large part about high quality regulate, stated co-founder and leader govt Erik Allen Ford. Dollar Mason sought after to do away with the opportunity of expensive-to-fix problems on orders of its common tees from outdoor factories. Shifting manufacturing in dwelling will have to make it imaginable to chop the time from design to manufacturing in part, and build up benefit margins via up to 10 p.c within the subsequent six to 9 months.

“We’ve been out and in of factories regionally for ten years,” Ford stated. “We simply suppose we will make the most efficient knitwear on the planet via proudly owning it vertically and proudly owning the standard.”

When direct-to-consumer manufacturers discuss “slicing out the intermediary,” they normally imply taking distribution or promoting into their very own palms. A small, however rising quantity are making use of this philosophy to production as smartly. Males’s grooming emblem Harry’s purchased a blade manufacturing facility in Germany in 2014; attire vendor American Large purchased a producer in Middlesex, North Carolina the similar 12 months; and shoes maker Rothy’s created its personal house in Dongguan, China in 2017.

Along with high quality regulate, having direct oversight of the availability chain can scale back delivery prices, get merchandise to marketplace sooner and assist you to head off issues. Working a manufacturing facility will also be tedious for manufacturers, however realizing the place their merchandise are within the production procedure supplies its personal peace of thoughts.

“At first, it was once identical to we wanted as a way to make the stuff that folks have been ready to shop for,” stated Bayard Winthrop, founder and leader govt of attire emblem American Large. “That surety of provide is a large deal.”

Who Will have to Open a Manufacturing unit

Vertical integration — the place an organization owns more than one phases of manufacturing and distribution — is a commonplace technique amongst giant manufacturers. Luxurious labels specifically have snapped up the entirety from flower growers to alligator farms and artisanal leather-based works to make sure get right of entry to to uncommon inputs, and that their baggage, footwear and fragrances meet exacting requirements.

Working a manufacturing facility is particularly formidable for model start-ups, which might be steadily based via marketers with experience in advertising and marketing or design, and would in finding holding a manufacturing facility buzzing extra of a distraction than an within merit. And whilst Chanel has numerous money to shop for a stake in a yarn producer, smaller manufacturers can steadily slightly come up with the money for to pay their present producers, let by myself spend thousands and thousands of bucks on house and gear to construct certainly one of their very own. Discovering professional staff may be difficult, particularly in the United States, which has noticed its attire production sector shrink for many years.

Vertical integration works best possible when manufacturers have established call for for his or her merchandise, and don’t have an extended record of essential investments competing for investment, reminiscent of opening retail outlets or expanding promoting spend, stated Benjamin Bond, a main person enlargement technique marketing consultant at control consulting company Kearney.

Dollar Mason, as an example, is successful and used its personal capital to shop for its knitting mill. Harry’s began as a subscription carrier, which made it more uncomplicated to are expecting call for for razors.

“If their call for is whatsoever variable and they aren’t seeing steady cast enlargement, then they will have to now not be making that funding,” Bond stated.

Streamlining the Provide Chain

Manufacturers steadily use in-house production for positive, vital parts in their provide chain, or as a spot to innovate, relatively than making an attempt to supply their complete product vary.

Dollar Mason doesn’t even plan to supply all of its tees, let by myself classes reminiscent of jackets or trousers, at its Pennsylvania mill. The emblem will proceed to make equipment like its leather-based belts and wallets in Italy and portions of its denim line and particular version leather-based jackets in LA.

“You’ll’t vertically combine and be international elegance in each and every class,” Ford stated.

The emblem’s sewers and architects can collaborate to assist you to forecast how a lot cotton it must supply or what it could actually do to ensure its tees last more.

Securing provide is every other motivation for making an investment without delay in production.

American Large — recognized for its vary of made-in-the-USA fundamentals — purchased its manufacturing facility in North Carolina in 2014. Previous that 12 months, the corporate was once taking a look to extend its order quantity of vintage zip-up hoodies at one of the crucial factories it labored with in San Francisco. The ones plans have been derailed when the manufacturing facility stated it needed to scale back American Large’s order capability to house Beneath Armour.

“It virtually killed the trade,” stated American Large’s Winthrop.

On the urging of an investor, and armed with undertaking capital, the corporate got a recently-bankrupt facility in North Carolina. Very similar to Dollar Mason, American Large’s facility has grow to be the designated hub for its knitwear pieces just like the zip-up hoodie, sweatshirts and tees.

Supporting Innovation

When Rothy’s — which sells footwear and purses made with machine-washable 3-d-knitted fabrics — was once launching its first slip-on sneaker in September 2018, it changed a usually guide serve as. The knit-to-shape generation within the corporate’s knitting machines have been ready to fuse a yarn within the higher of the footwear, permitting designers to fasten stretch in positive spaces and now not in others. Through doing so, the corporate decreased the choice of folks it had to make the footwear and considerably reduce down on waste, stated Roth Martin, Rothy’s co-founder and president.

Such efforts have come as the corporate scaled its manufacturing facility from one ground with 9 machines to round 300,000 sq. toes and just about 700 workers. Rothy’s continues to take a position a portion of its annual income in increasing its production functions.

“We’re all the time innovating on our merchandise like a tech corporate may have model releases,” Martin stated. “We wish to learn to actually transfer the needle in doing what we do.”

#shorts #shortsfeed #nature #youtubeshorts #iciness

#shorts #shortsfeed #nature #youtubeshorts #iciness